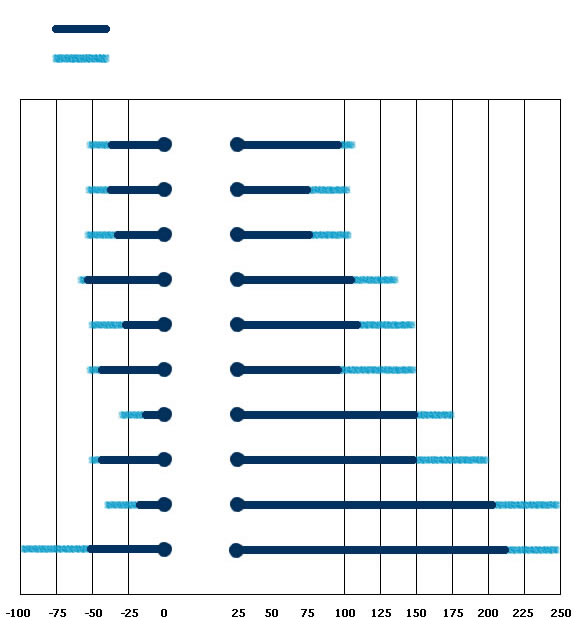

TEMPERTURE RESISTANCE OF RUBBER MATERIALS................

| Rubber Materials | Code Name | Code Name of ASTM |

| Natural Rubber | NR | AA. |

| Polyisoprene Rubber | IR | AA. |

| Styrene Butadiene Rubber | SBR | AA. |

| Polybutadiene Rubber | BR | AA. BA. |

| Butyl Rubber | IIR | BA. |

| Ethylene Propylene Rubber | EPDM | AA. BA. CA. DA |

| Polychloroprene Rubber | CR | BC. BE. |

| Nitrile Rubber | NBR | BF. BG. BK. CH. |

| Polyurethane Rubber | PU | BG. |

| Hypalon. Polyethylene | CSM | CE. |

| Polyacrylate Rubber | ACM | DF. DH. EH. |

| Silicone Rubber | SI | FC. FE. GE. |

| Fluoro Carbon Rubber | FKM | HK. |

HOW TO SELECT RUBBER MATERIAL..............................

| I. | The service conditions to be considered include: 1. Fluid to be sealed, including any contaminants or additives. 2. Temperature range including minimum and maximum operating conditions, as well as thermal cycling and potential excursions. 3. Pressure range - ingluding minimum and maximum operating range with an error range and compression/ decompression rate if the pressure is high. 4. Vacuum application - including where the vacuum is applied and whether it is cyclic. 5. Motion - either static or dynamic. If it is dynamic, describe the motion. |

| II. | The design requirements of the particular sealing application are also critical including: 1. Component geometry/ description, like O-ring, gasket, diaphragm, etc. 2. Chemical media's affect on the seal. 3. Desired service life. If it is a replacement for a failed seal, which material was used before and why did it fail. 4. Assembly considerations including lubricants, installed stretch, etc. 5. Critical dimensions and tolerances, including groove dimensions and machin- ing tolerances. |

| III. | It is important to consider the inspection requirements including: 1. Defining inspection criteria. 2. Determining the need for lot sampling. 3. Setting acceptable quality levels (AQLs). 4. Indicating the critical sealing surface. |

| IV. | Material specification and traceability are also critical for proper seal selection. 1. Define material specifications by the American Society for Testing and Materials (ASTM). Society of Automotive Engineers (SAE), military specification or other recognized standards. 2. Discuss with your seal supplier the procedure for specifying and certifying sealing materials. 3. Ask your supplier if compound changes may without a customer's knowledge and how to protect yourself from it. Are hardness buttons, tensile bars or other test specimens required for incoming material verification. |

| V. | Cost versus Value: When selecting materials for your particular sealing application, the guiding principle should be "value-in-use." When evaluating seal performance, seal life and maintenance costs must be included. A seal made from EPDM may be appropriate for many general applications where heat and steam are encountered, but inappropriate at higher temperatures when contaminated steam are frequent maintenance are required. The relatively high price of a fluoroelastomer or perfluoroelastomer will be recouped many times over by a seal's long service life. Specifying the proper high performance seal can also prevent costly unscheduled downtime and dangerous leakage. |

When selecting elastomeric seals for specific applications, there are a number of important selection criteria including the anticipated service conditions, the design and inspection requirements for the particular application and material specification and traceability.

Download the Rubber Material Properties PDF file.............................................